The new vertical centrifugal wood pellet machine is the latest wood pellet machine in China. The wood pellet machine adopts a large modulus hard toothed helical gearbox, strengthened spindle, strong power output, equipment stable operation, low failure rate, low production cost. Suitable for: eucalyptus, pine, birch, poplar, fruit, crop straw, bamboo chips, rice husk, waste wood plate, etc

Подробности:

|

1.Parallel vertical installation reduce energy consumption loss

The motor and main shaft of wood pellet machine supplier are parallel vertical installed , which can reduce energy consumption loss in the process of transmission, more output power, higher transformation of energy efficiency.

2. Siemens Brand Motor:

This kind of motor of wood pellet machine is frequency and has thick copper coil, motor of wood pellet maker won’t be burned due to instantaneous current.

3.Casting material of gearbox with high stability

Gearbox shell of pellet press adopts casting with good rigidity, good heat dissipation, Low heat distortion and high stability.

4.High automation, no need to take care

Control panel, tablet computer and mobile APP of wood pellet making machine can be used to monitor the temperature of critical parts and the electric current of the equipment

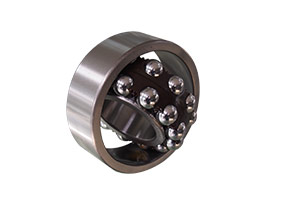

5.Cooling system of gearbox enhance the internal bearing life

Gearbox Lubricant of the wood pellet machine adopts bypass water cooling system to avoid oil temperature is too high, greatly enhance the internal bearing life.

6. Reducer drive of pellet machine strengthen with 3 level.

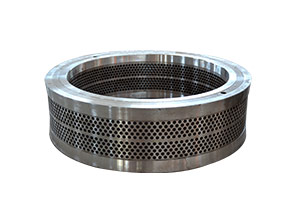

7. Stainless steel Die of wood pellet machine with high wear resistance and high capacity.

Сырье:

Wood

Sawdust

Sawdust

Sawdust

EFB

Bamboo

На что способны гранулы биомассы?

Boiler

Fireplace

Heating system

Power plant

Подробности:

| Model | Power(kw) | Pellet Size(mm) | Capacity(t/h) | Size(mm) | Weight(t) |

| YGKJ560 | 90/110 | 6-12 | 1-1.5 | 2200*1300*1600 | 5.8t |

| YGKJ700 | 132/160 | 6-12 | 2-3 | 2400*1400*1800 | 7.8t |

| YGKJ880 | 220 | 6-12 | 3-4 | 3000*1500*2300 | 12 |

Введение в аксессуары:

Harbin Bearing

Mould

Oil injection system

Siemens Motor

Экспортный случай:

8t/h wood pellet production line in Philippines

10t/h wood pellet production line in Thailand

10t/h wood pellet production line in Malaysia

10t/h wood pellet production line in China

Экспоненты:

2019.3 Japan Exhibition

2019.6 Indonesia Exhibition

2019.12 Russia Exhibition

Exhibition

Вопросы Ответы:

Q: Are you manufacturer of trading company?

We are manufacturer, also with marketing department and R&D center.

Q: I am newer to biomass industry, how to design the suitable plant?

Do not worry about that. We already helped many beginners. We provide optimal project design according to every customer’s needs.

Q: Do you offer installation and training?

Yes. We can dispatch technicians to customers' site to help install equipment and train how to operate.

Q: How can you guarantee the after-sales service?

We have professional After-sales service center with experienced and skillful engineers. When problem of equipment occurs, our engineers will be assigned to your site to solve problems timely. Also spare parts can be provided timely due to oversea warehouses.

Q: Are there some machines in my area I can observe?

Rotex Master have machines in many countries, if there are machines in your country, we can contact the customer to arrange a visit for you.

Q: Which kinds of raw material can be used for making pellets?

Sawdust (waste wood chips/shavings), other forest waste, agricultural straw, stalk, bamboo, peanut shells, rice husk, bagasse, alfalfa, palm fiber etc.

Q: What is the main process for making pellets?

Coarse Crushing Section(Splitter, Wood Chipper)—Drying Section—Crushing Section—Pelletizing Section—Cooling Section—Packing Section

Q: What is your work flow?

Inquiry—Quotation—Communication—Order Confirm & Payment Received—Production—Production Tracing & Inspection—Check Every Product—Book Vessel & Arrange Delivery—Documents Post/Telex Release—Customs Clearance—Arrange Delivery to Clients` Site—Discharge Goods—Arrange Installation & Debugging

Q: How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in 5 working days after signing the sales contract, the balance of 70% will be paid before the goods leave the factory.

(2) 30% deposit of the total amount to be paid by T / T 5 working days after signing the sales contract, the balance of 70% can be paid by L / C before the factory leave goods.

(3) We can negotiate specific payment terms with our client.

Q: How long is the delivery time?

For standard machines, that would be 25-30 working days; For non-standard machines and customized machines according to customers' specific requirements, it would be about 30 working days.

we work with the biggest freight forwarder in North China. if you need to appoint other freight measures, we can arrange them because we have rich experience and sufficient funds to handle.

Q: How about the documents after shipment?

After shipment, we wi ll send all original documents to you by DHL, including Bill of Lading, Commercial Invoice, B / L, and other certificates as required by customers.

Получите мгновенное предложение

По всем вопросам заполните форму ниже, чтобы отправить нам короткое сообщение, и мы свяжемся с вами в ближайшее время.